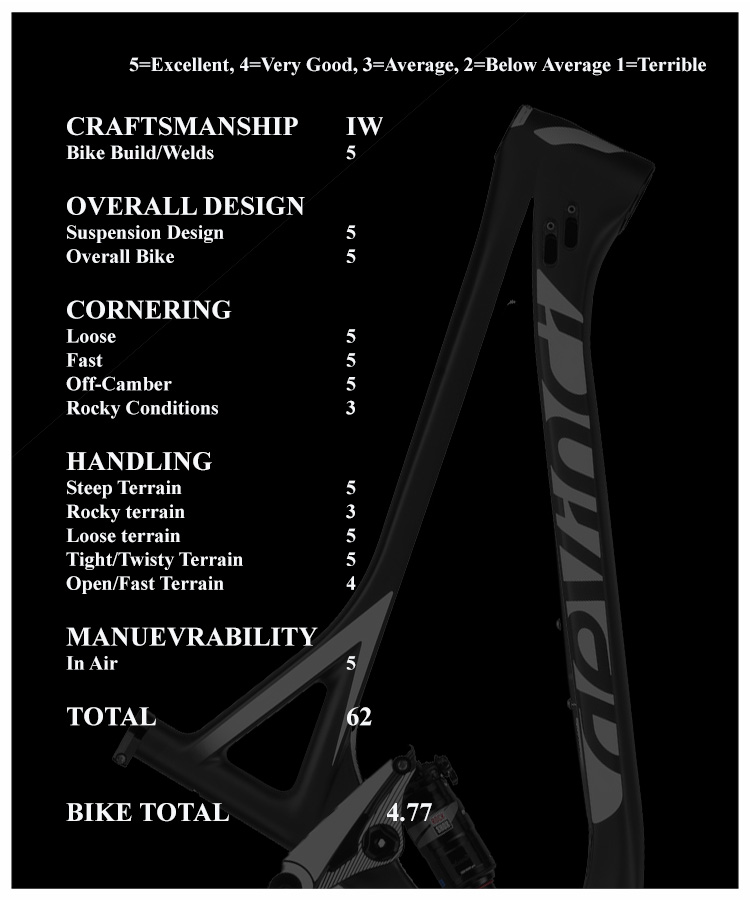

Devinci Django Review

Saturday, July 9, 2016 at 5:02PM

Saturday, July 9, 2016 at 5:02PM  Permalink

Permalink The mountain bike market as we know it has changed and become much more specialized over the last five years. Bikes are now broken down into very specific categories and the only bike that now seems to cover two genres is the Enduro bike. It is a climber as well as a descender with a stronger emphasis on going down.

Devinci released the Django as an aggressive trail bike. these are shorter, lighter version of their Enduro counterparts. These bikes will climb better and be a bit easier for longer rides in general. They do however give up a fair amount of comfort once trails get rocky and rowdy!

We took a break from the longer travel Enduro bikes and decided to test out Devinci's go at a short travel all mountain slayer the Django. it was noticeably lighter than our last bike and was a full factory build. We had to get used to Shimano brakes and drive train again but that only took a few rides.

Devinci History

"Aluminum was the seed that set a two-wheeled revolution in motion, when Devinci Bikes landed in Chicoutimi, Quebec, more than 25 years ago. From road to race to carbon and dual-suspension line-ups, today Devinci stands as a global frame-manufacturing leader, home to cutting-edge R&D facilities and a top engineering squad committed to the ultimate ride.

Its story starts in 1987, when Devinci began life as Da Vinci (as in Leonardo), a company envisioned by two local engineering students. Soon after, road biking entrepreneur, Felix Gauthier, entered the mix. By 1990 he had purchased half the company, swapped vowels, and Devinci proper was born.

From the outset it wasn’t always smooth roads for this fledgling Canadian-born brand. Perfecting the heat-treatment processes was a game of trial and error. Money was tight, distribution channels were slim, and when a costly new oven threatened to break the bank, Gauthier and his team combined ingenuity and talent to build one themselves. With a growing set of tools and skills in place, Devinci went to work cooking more bikes. By 1993, distribution had expanded, Gauthier had taken sole ownership of the business, and Devinci moved from its modest 800-square-foot home to one four times the size.

Brainpower was corralled; designers and skilled technicians were sourced; R&D was ratcheted up, reinforcing a commitment to quality and performance. From Canadian market exclusivity, Devinci branched worldwide, expanding its road repertoire to include an array of women-specific rides, hybrids, XC standouts, ergonomic cruisers, and a World Cup winning dual-suspension mountain bike lineup—featuring Dave Weagle’s patented Split Pivot technology.

Today Devinci’s creative engine revs under one roof. This includes a state-of-the-art on–bike testing system, which measures every stress and strain in real life situations. Changes to a particular design can be prototyped, tested, tweaked, and re–tested in days rather than weeks.

This detailed ethos equates to value and efficiency, as well as industry-leading quality control and R&D efforts poured into every bike launched at Devinci HQ."

Devinci Django

"Freedom on the bike is all about breaking from the starch and sending it into the dirt-sphere with power, speed, and finesse. Devinci’s new Split-Pivot Django actualizes those aspirations on the trail, with an optimal blend of 130mm front/120mm rear suspension. Surefooted 27.5 wheels enhance traction on wet, slippery surfaces and deliver appreciated stability. And alloy and carbon frame architecture augments punchy acceleration with precision handling and a lively overall feel. Whether sticking fierce, fast descents or finding optimal flow over upturned environments, Django seizes the opportunities ahead. Its lifetime warranty fuels the advance. *Image may not show accurate specifications. Please refer to specifications below."

Django XT Build Kit

- Carbon DMC-G 120mm

- RockShox Pike RCT3 27.5 Solo Air 130mm

- FSA Orbit 1.5 Zero Stack w/SL bearing

- RockShox Monarch RT3 7.25x1.75 DB High Volume Eyelet

- Schwalbe Hans Dampf 27.5x2.35" Trailstar SnakeSkin TL

- Schwalbe Rock Razor 27.5x2.35' Pacestar SnakeSkin TL DT

- Swiss X1700 Spline 27.5 15x100mm

- Shimano RT81 180mm Centerlock Shimano XT M8000

- Shimano RT81 160mm Centerlock Shimano XT M8000

- 11s Shimano XT M8000

- RaceFace Next SL 30T

- Shimano 11s 11-42T

- Shimano 11s

- Race Face Next ¾ Rise 31.8mm 725mm

- Race Face Turbine 31.8mm

- SDG Bel-Air Rock

- Shox Reverb Stealth 125mm 31.6mm

- Alloy CNC 37mm Black

- Devinci Performance w/lock-on

- 12.38 kg / 27.29 lbs

Devinci Django Frame Features

- 5th generation of all mountain Split Pivot frame. New geometry with a top tube 20 mm longer on all sizes to fit a wider range of customers

- Tapered head tube Precise control and the best strength-to-weight ratio in the business

- Lower stand-over height Delivering prime stand-over fit, and a super-low center of gravity for enhanced handling

- DMC-G Devinci monocoque carbon. Lighter, stiffer, more responsive. Featuring EPS molding with T700 carbon fiber

- Ultra-short chainstays Pin-it acceleration, combined with superior driver's seat handling

- Split pivot Suspension system. Separates acceleration forces from braking forces for synchronized feel

- AXIS & FRG ADJUSTABLE Perfect balance, minimum unsprung mass, and prime hi/lo geometry adjustment for perfect settings

- Boost 148 standard Stiffer rear wheel

- Internal cable routing Protection from elements. Deluxe, aerodynamic styling

- Asymmetrical construction Milking the most performance out of every frame angle, improved torsional stiffness

- 27,5 dedicated 2.35'' maximum tire clearance

- Increased bottom out force Increased progressivity for improved bottoming out forces

- CUSTOM TUNED REAR SHOCK

Split Pivot Suspension

"SPLIT-PIVOT is a newly patented Dave Weagle suspension system for high performance bicycles, where traction, efficiency, maneuverability, and frame stiffness are important factors on the track and trail. Shaped by DW's competition proven engineering, SPLIT-PIVOT offers true performance advantages over single pivot bikes, with a ride that's sure to make you smile.

- SPLIT-PIVOT's [concentric dropout pivot] is the heart of this new design. The [concentric dropout pivot] and Dave Weagle's engineering allow for performance features that no single pivot can duplicate.

- SPLIT-PIVOT separates acceleration forces from braking forces in the suspension The system reduces excess suspension compression due to acceleration forces, and at the same time reduces excess compression due to braking forces.

- Braking neutrality can be tuned independently of acceleration characteristics, and leverage rate curves can be tuned to meet the needs of the application.

- SPLIT-PIVOT can be engineered to build lightweight frame structures without resorting to exotic materials or tube shapes.

- Featuring 12mm thru axle, QR 12mm axle, or 10mm vertical QR possibilities, plenty of stock wheels fit the design.

- Bottom Line: SPLIT-PIVOT is a patented DW suspension that can be engineered to offer a ride that will make you want to be on your bike more often."

Devinci Django Geometry

The first trail climbs about 700 feet in just over 1 mile and I could tell The Django had a 5 lbs weight savings over the bigger bike. It's overall platform felt much stiffer as well and a bit less forgiving while climbing. I was only a minute behind my normal time of 18 minutes to get up which is not bad considering how much time I had off.

Once at the top I strapped on my bell and goggles and got ready to drop in. The first part is high speed and fire road width with a good scattering of rocks. I could tell right away The Dgango was a bit less forgiving when hitting bigger rocks than the past bikes we have tested. It was time to hop over these instead of just steam rolling them like we do with the bigger bikes.

The trail takes a hard left through rocks and enters a very high speed off camber single track section. there are some large rocks here you dodge and weave your way through. After that it goes right back across the mountain through some ruts and up and over a steep roller that acts as a G-out and typically uses most of a bikes suspension when hitting it at speed.

This trail is somewhat smooth compared to others in the area. I was able to get within a few seconds of my fastest time on my second time down the trail so this is a bike that inspires confidence.

Overall the bike seemed to provide a solid pedalling platform. Whether standing or sitting the bike bobbed very little we ran it in pedal mode on the rear shock about half the time. On a few occasions on the descents we left the shock in pedal mode just to see how it would feel and honestly you couldn't tell except for the small bump sensitivity.

The Devinci Django proved to be a more trail oriented type of bike. It's shorter travel and firm suspension stroke begged for smooth line choices and pumping your way down the trail to keep up the speed. Having ridden the more aggressive Enduro bikes recently what we came away with was that The Django can make for a rougher ride over rocky terrain. Smoother terrain and flow based trails are where The Django shines. It can carry speed and cover terrain very quickly with a skilled rider behind the bars. The Split Pivot Suspension designed by Dave Weagle feels good. Setting up the bike was pretty easy. We actually didn't need to add any rings into the rear shock. We ran between 25%-30% of sag on the bike. It was very progressive and we never had an issue with excessive bottoming out on the trail.

Riding The Devinci Django it became apparent that Weagle's design goals of a stiff, efficient and neutral braking frame have been achieved with The Django. I weigh 220lbs and can usually detect frame and wheel flex pretty fast. The Django felt very stiff and gave a very neutral braking feel. Acceleration, and climbing while providing a firm pedaling platform is something the Django does well. The tradeoff is that the bike provides a stiff ride on the way down and you have to be hauling ass to get the suspension to soak up the smaller stuff. This won't bug most riders but it should be noted. If you live in Santa Cruz or flow filled Nirvanas then it won't be an issue.

The Devinci Django is a fast bike it wants to be pressed into the turns and pumped out of them. Tires are something that can get chewed up around here fast. The trails are very rocky so we yanked off the back tire and ran a GRID casing Specialized to play it safe. It added some weight but was well worth it. With our Hope flat pedals our XL complete bike weighed 31lbs.

Conclusion

Overall we liked The Devinci Django with its short travel can do attitude. It was very playful and poppy, a bike you could launch off or over anything to big to run over. Carrying speed helped to keep the suspension active and absorbing all the terrain passing under your tires. Pumping your way down while avoiding the big stuff will keep you covering ground in a hurry.

People looking for a short travel aggressive trail bike that can handle 50 mile days and descend most terrain easily will love The Django. It provides a stable pedalling platform in a stiff chassis. Rider input is instantly translated into bike movement overall it is a very lively ride. Devinci did a good job with the bikes overall geometry. We ran wider bars and beefier tires to avoid sidewall tears.

It has been close to a decade since I have ridden a Shimano drivetrain and I was surprised by how will the XT 11spd worked. It clacks much harder between gears than SRAM stuff does so that took a bit of time to get used to. Overall the build was good. One thing worth replacing would probably be the wheels just beat the hell out of them and swap them for something wider and stiffer down the road.

There are some very rocky tails in this area and that is when you will notice the short travel of the Django. Hitting that stuff at speed transfers chatter into the bars and pedals. This was the only time we found the short travel holding us back. Overall it's agressive geometry, great suspension and stiff chassis make The devinci Django one hell of a fun ride.

We would reccomend The Django to a friend looking for a short travel bike. If they are looking at XC bikes I would suggest they check one of these out. If they already own a DH bike but want something to train on the Django could be the answer! Shortly after we got the 650b bike Devinci announced The 29" Django which should prove to be a bit better as smoothing out rough trails. Another bike sporting a Dave Weagle suspenion system that is awesome imagine that......

Devinci Django Questions

1. Give us a Devinci history lesson.

http://www.devinci.com/company/index.html

2. How do bikes go from ideas to production at Devinci?

https://freehubmag.com/videos/made-love

3. How did the idea for The Django begin?

With the Troy being updated with a burlier frame and now being more at the All-mountain crowd, it left a space for a new bike in our offering. Being based on the east coast, we wanted a bike that would be punchier than the Troy to handle the rolling terrain that we have here. That’s when we decided to go with a smaller travel bike (120mm in this case) that would remain very capable but would give a better punch.

4. Was it a hard choice to decide on a 120mm travel bike for you guys?

No, as previously said, this falls naturally in our lineup.

5. What where some of the main features you guys wanted in the Django when you were laying it out on paper (computer)?

We wanted a bike that feels more capable than the typical 120mm bike but also that feels very lively. A bike that makes the climbing less painful and bring some fun to it. True to Devinci’s design, we wanted to have short CS and low BB as well as low stand over height to make sure the bike is fun to ride.

6. Did you achieve all the elements into the final product?

We did and we are stoked on the final product. No need to say that this bike has been the ‘go to’ option for many of our staff.

7. Any updates you guys are looking to do to the Django in the near future?

The Django saw a few spec change for 2017 like dropper post and wide bars on all models, including entry level. Other than that we are pretty stoked on the bike.

8. Care to elaborate on geometry used on the Django?

We wanted something that feels capable but remain nimble and fun. So short CS, low BB, HA that enable to handle the steeps while remaining lively on the trail.

9. Rocky or jump filled trails?

Jump filled on the 27.5, Rocky on the 29er.

10. Where are your carbon bikes made?

Aluminum are 100% made in Canada. Carbon bikes are designed, tested, assembled in Canada but frames are manufactured in Asia.

11. Who is the best Mountain Biker ever?

Stevie Smith

12. Any new bikes you want our readers to know about?

All our 2017 models are now online, check it out !

13. What do you think about all the new standards that have popped up in the last 3 years?

As long as it makes the ride and the bikes better it’s worth it. However it is definitely a challenge for us in terms of frame conception and parts spec.

14. What would make the bike industry better?

More trails and more people to maintain them.

15. Will Devinci be making a long travel 29” anytime soon?

Only future will tell.

16. Anything else you want to get across to the readers?

Have fun on the trails !

27.5,

27.5,  650b,

650b,  Devinci Cycle,

Devinci Cycle,  Devinci Django,

Devinci Django,  Django,

Django,  Enduro,

Enduro,  Mountain Bike,

Mountain Bike,  Split Pivot,

Split Pivot,  Trail MTB |

Trail MTB |