2016 Guerrilla Gravity Downhill (GG/DH) Review

Tuesday, February 2, 2016 at 5:11PM

Tuesday, February 2, 2016 at 5:11PM  Permalink

Permalink Guerrilla Gravity is a small mountain bike company located in Denver Colorado. They were sick of frame prices shooting through the roof while production moved overseas with little, if any, performance increase from year to year. All this while many bike companies grew in size and became more distant from their customers and what they really wanted in geometry and suspension designs. Who wants to buy a frame for $3500 and have part of it go to subsidize some road racers salary anyhow?

We tested their Megatrail last year and it proved to be an insane trail rig. Not only was it insane descending, but when using Trail mode it was one of the best climbing enduro bikes we have ever ridden. The guys at Guerrilla Gravity emailed and asked if we would be interested in testing out their updated 2016 GG/DH frame? Hell yes we would!

Andrew Soto Shredding The GG/DH

Andrew Soto Shredding The GG/DH

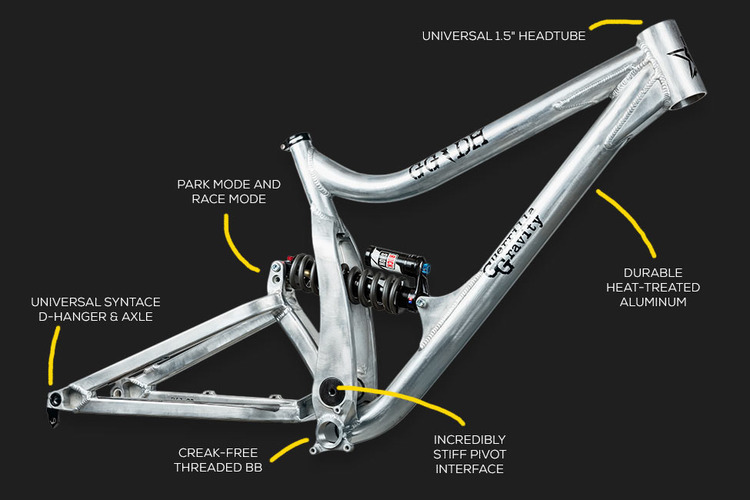

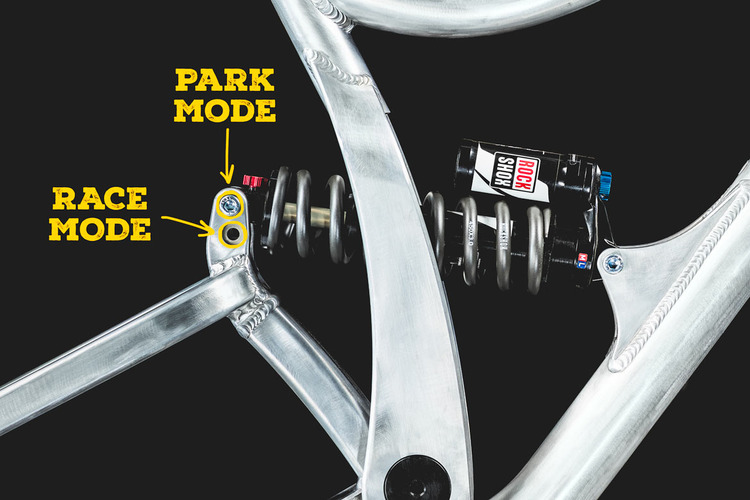

Upon receiving the GG/DH we opened up the box and found a clean looking frame with great welding and paint to match. Guerrilla Gravity had four updates that it did wit the 2016 GG/DH frame. The first was to remove the shock mount eccentrics for BB height/HA adjust and replaced it by adding two holes for Park Mode and Race Mode geometry adjustments. Just like the Megatrail uses. They also increased tire clearance and optimized the frame for 650b wheels. The last update was to the rear axle and was aimed to improve it's function.

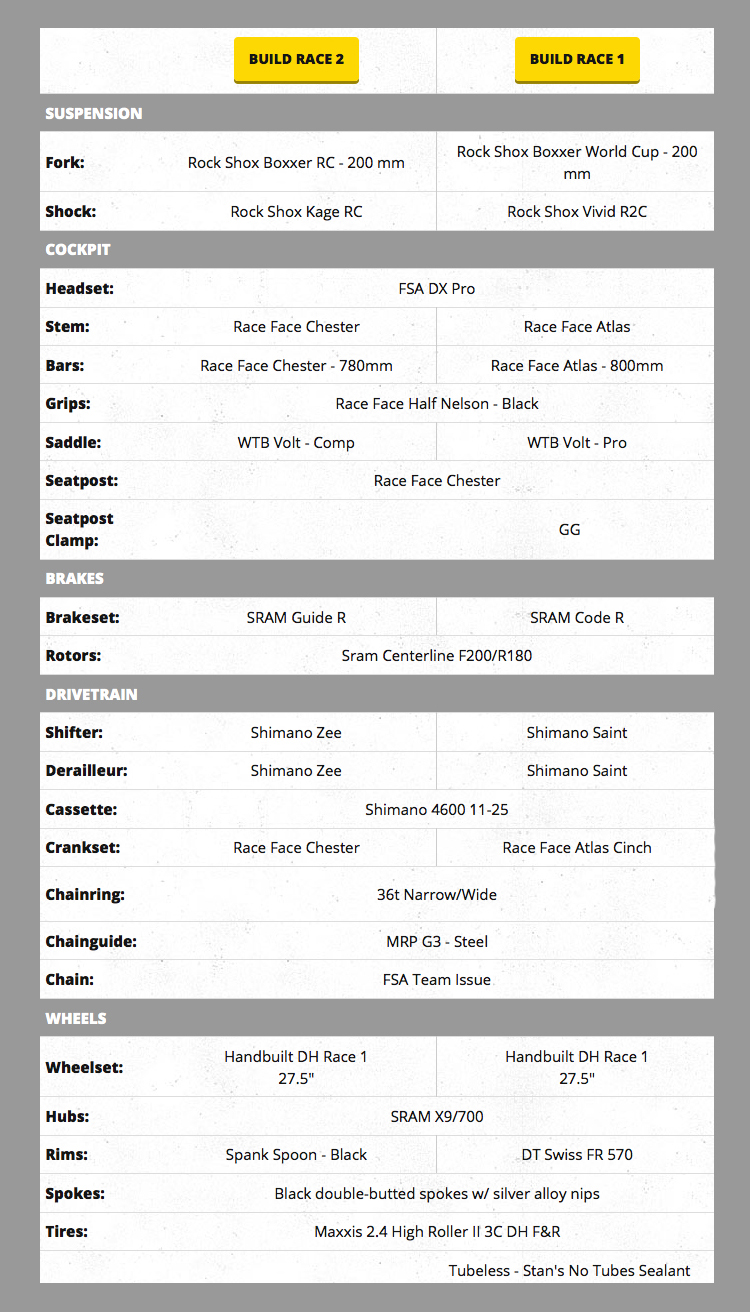

2016 GGDH Build Kits

The guys at GG sent us the bike with a blend of the two kits. It had the Boxxer WC, Atlas controls, Zee shifting and the nicer wheels. It had the Kage RC shock on it as well. Our medium GG/DH with Hope flat pedals came in at 37.5 LBS. Overall the build kit is decent the one thing we would swap out is probably the rear shock. It would be nice to have separate HSC and LSC adjustments to fine tune the bikes ride with. After riding trail bikes for so long with air shocks it is a surprise to see how much traction this bike gives even on the steepest and loosest of trails. Maybe there really is something to coil shocks......

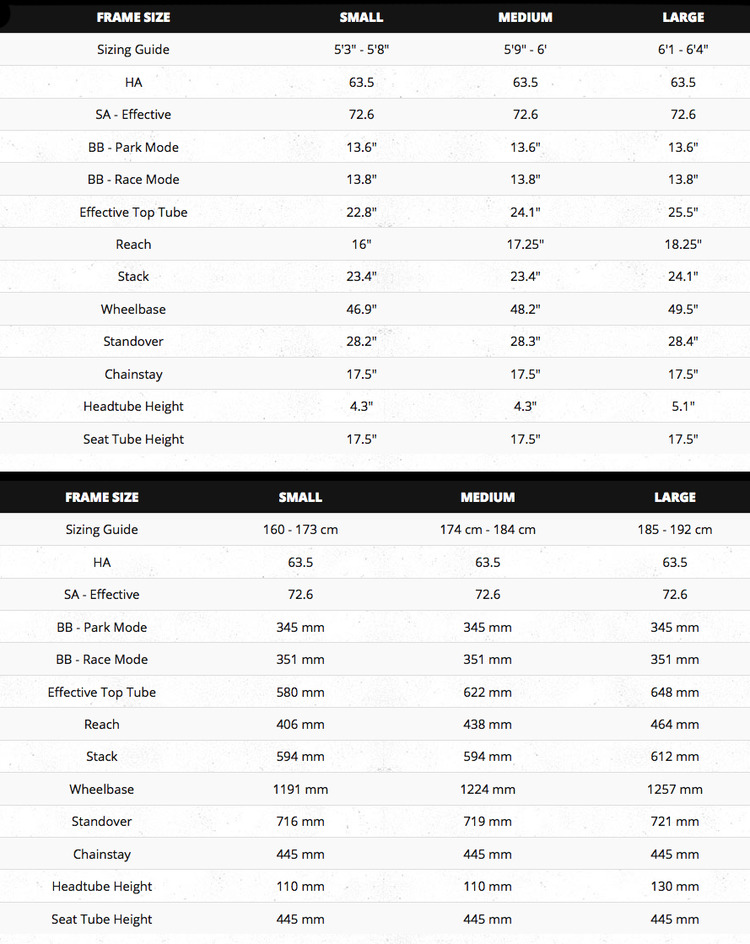

I am 6' 1" tall and the MD fit me okay. I think I would buy the LG as a personal bike and run a shorter stem possibly. I am right between sizes so that always makes it tricky. Andrew is 5' 9" and said it felt great. Having a TT of 24.6" on a MD makes it close to 1" longer than many companies MD offerings and it is the same size as the large Specialized Demo.

"The GG/DH is a refined machine built for riders that like goin' fast.

With a suspension platform that is progressive and a frame that is laterally stiff, the GG/DH is designed to carry speed and pop off bonus lines at will. The enclosed rear triangle provides snappy cornering and rails lines better than John Belushi.

The frame design eliminates all unnecessary complication, creating the bike for those that like to get out and ride day in and day out, for riders that want something that's high performance, yet easy to maintain. By eliminating the need for additional pivot hardware, you are left with one pivot that utilizes long-lasting Enduro bearings. Limit your time inside doing maintenance and go ride.

The ride characteristics provide a lively, nimble platform that pedals extremely well for its downhill capabilities. The geometry is low, slack, and adjustable. Choose between Park Mode and Race Mode via the rear shock mount adjustment that are easy and quick to change."

Forward Geometry Benefits

- Security in steep areas

The front axle is more advanced than in a conventional geometry making it almost impossible to go over the bars in steep sections. It feels more secure and confident due to a slacker angle perception.

- Confidence at high speed

The longer wheelbase makes the bike much more stable over any terrain.

- Direct steering

The really short 10 mm, 30 mm or 50 mm stems mean much less handlebar movement to get the same front wheel angle, thus improving steering precision and making the bike extremely reactive.

- Uphill precision

The front wheel keeps the contact on the ground avoiding wheelies due the longer front-center length.

- Stability on rough sections

The FG defends a new weight balance between front and rear wheels making possible to load the front wheel a lot more than with a classic geometry. This possibility changes your handling as it allows for more grip in cornering and better control.

Andrew Soto Shredding The GG/DH

Andrew Soto Shredding The GG/DH

GGDH Features

- 203 mm (8") rear travel

- Dual modes adjusted via shock mount

- Race Mode

- Park Mode

- Threaded bottom bracket, greatly reduces creaking and loosening (vs press fit)

- Massive 25mm pivot axle

- Zero Free Play pivot and axle interfaces

- Premium Enduro dual-lip sealed cartridge bearings

- 7.9 lbs. (3,583g) frame with hardware (size Medium, no shock)

GGDH Specs

- 30.9 mm seatpost (34.9 mm clamp)

- 1.5" head tube (49 SHIS - compatible with all steerer tubes and the Cane Creek Angleset)

- ISCG05 chainguide mount

- 148 mm rear wheel spacing

- 83 mm bottom bracket spacing

- 240x76 mm shock

- Max tire size: 27.5 x 2.5

GGDH Geometry

Similiar to the Megatrail the GG/DH offers two travel/geo options. One is Park and the other is Race. While riding the Mega we noticed a huge difference in the two settings and we where wondering if the same would hold true for their downhill bike.

Andrew Soto Shredding The GG/DH

Andrew Soto Shredding The GG/DH

GGDH Owner Information

Proper suspension set-up is critical for optimum performance. Due to variance in shock pump readings, we suggest using a ruler and a friend to help set sag.

Recommended front fork sag is 15%. Recommended shock sag is 18-20 mm.

To set sag:

- Step 1: Compress the suspension several times to break the seal and get oil flowing

- Step 2: Have a friend hold the bike while you stand in the attack position, both feet on the pedals

- Step 3: Have said friend take the eye-to-eye measurement of the rear shock in millimeters. Subtract this number from 76 mm. You now have your sag

- Step 4: If you're using an air shock adjust the air pressure using your shock pump to achieve the recommended sag setting (listed above). It may take a few times.

Shock specific setup info:

- Cane Creek DBcoil: Cane Creek shocks purchased with a frame come preset with the base tune--you just need to set sag and tweak the damping settings to your weight, with gear weight taken into account. The base tune is dialed in for a rider weight of 175 lbs. Adjust +/- 2 clicks of low speed settings and 1/4 turn of high speed settings for every 20 lb increment of rider weight difference from 175 lbs. Email us to talk further about shock settings for your unique riding style and terrain.

- Cane Creek DBair: Cane Creek shocks purchased with a frame come preset with the base tune--you just need to set sag and tweak the damping settings to your weight, with gear weight taken into account. The base tune is dialed in for a rider weight of 175 lbs. Adjust +/- 2 clicks of low speed settings and 1/4 turn of high speed settings for every 20 lb increment of rider weight difference from 175 lbs. Email us to talk further about shock settings for your unique riding style and terrain.

Andrew Soto Shredding The GG/DH

Andrew Soto Shredding The GG/DH

Ian W

The first trail I took the GG/DH out on was one that I have not ridden in almost three years! This trail is steep, rocky, loose and nasty. It drops 1350 feet in 3/4 of a mile. It is littered with sharp embedded rocks and has a heavy layer of loose shale in sections. There are very tight turns in some sections and a few high speed steeps that have some soil. Overall it is a great trail to test a bikes GEO and suspension out on. I was in a bit over my head trying to ride this trail after so long. You drop into the trail and it enters a high speed section that is littered with good size rocks. The GG/DH did a good job at absorbing the harsh high speed impacts. There is a small uphill then the trail turns downhill in a very steep fashion for about 100 yards. This section was covered in loose shale and hard embedded rock. I went in slow and used front and back brakes. What shocked me most was the traction! Holy hell the rear tire just kept gripping the whole way down. Overall the bike felt great on the steep chunky terrain it reminded me of the Bruce Lee quote “Be like water making its way through cracks. Do not be assertive, but adjust to the object, and you shall find a way around or through it." Riding down this chunky trail I was reminded how easy it is to adjust most single pivot bikes. Everything felt good from small bump, bottom out and the GG/DH offered stability in spades.

San Luis Obispo offers rocks and lots of them. There is a trail in town that is 1000 feet and has baby head boulder most of the way down the trail. It isn't very steep so a burly trail bike has some overall speed advantage but riding a DH bike on it reminds you how much better they are at eating up rough terrain compared to Enduro bikes. Riding behind a 150mm bike while on a big bike you can watch the rider moving around to help absorb the trail while you sit back and move only if needed. Again I noticed the rear offering good traction when needed. I was actually suprised by The Boxxer WC it felt very good. Super supple and offered decent mid stroke support. Matt at GG said the leverage curve is what gave the bike such confidence inspiring grip. Another thing of note was how easy it was to change lines with the bike. I could hop it over and off rocks easily even in Race Mode.

The bike was very playful in both modes. Using it in Park Mode it is a bit more poppy and easy to move around but it is not as huge of a job as we noticed while testing The Megatrail last year. I am not sure I would run it in that setting a whole bunch unless the terrain you where riding was loaded with jumps the whole way down.

Conclusion

After ridng the Megatrail and being so impressed with it we really where not surprised to find the Guerrilla Gravity downhill bike to be so dialed. The geometry isn't super aggressive either with BB height or head angle but the frame is long. I was a bit nervous getting the medium frame but it turns out their sizing recommendations for the GG/DH are pretty spot on. We have had a YT Tues for almost 8 months now and it is a size large. The GG/DH in a size MD feels the same or maybe a tad longer in the reach department and on paper it is.

Overall we where very impressed with the GG/DH. It's strong point would be it's forward geometry and stiff frame. Point the bike along boulder edges and it will try its hardest to hold onto them. Come into a corner to hot and have to break the rear end loose to make the turn no problem. Guerrilla Gravity did a good job building a stiff chassis by using a huge 25mm pivot axle and oversized tubing. We noted how stiff the Megatrail chassis was and I would say the GG/DH is one of the stiffer DH frames we have ridden.

Traction is something this bike offers by the truckload. I was blown away going down the steep shale trail with brakes on hard that it was sliding all over the hill. This is somewhat due to its coil spring but also its very supple suspension curve. A nice thing about Single Pivot bikes and their suspension curve is how easy they are to set up. Typically we run a bit more LSC with them and since they are somewhat linear feeling we can add more HSC or bands into an air shock to resist bottoming while still keeping a bunch of traction. The frame we tested was a MD GG/DH and it fit me well. I am six foot one inch and I could probably ride the LG as well with a shorter stem on it. Again the GG MD is the same size as The Specialized Demo.

It is for sure a bike we would reccomend to a friend and it being made here in the sates is a nice added touch that is getting harder to find by the year.

Guerrilla Gravity Downhill Questions

3. Break down your team for us and what they do?

4. How did the idea for the GG/DH begin?

5. What where some of the main features you guys wanted in the GG/DH when you were laying it out on paper (computer)?

- Geometry built for speed

- Predictable suspension performance with high traction and support

- Stiff & strong frame

- Versatility for a more poppy Park setup or a more plowy Race setup

6. How was reception been on the GG/DH so far?

7. Do you weep when you see guys that are 6' 4” and above on a “XL” bike and they look like Spud Webb on a 16” BMX bike?

8. Are you going to be doing an XL frame soon?

9. Any updates you guys are looking to do to the GGDH in the near future?

10. Care to elaborate on Geometry used on the GG/DH?

11. Rocks or jumps? How about jumps in rocks?

12. Who is the best Mountain Biker ever?

13. What do you think about all the new standards that have popped up in the last 3 years?

14. What would make the bike industry better?

15. Anything else you want to get across to the readers?

Guerrilla Gravity DH Owner's Manual