WTB Vigilante Tire Review

Wednesday, March 2, 2016 at 5:50AM

Wednesday, March 2, 2016 at 5:50AM  Permalink

Permalink

Wilderness Trail Bikes has been around a long time. They came to creation in Marin county what many consider to be the possible birthplace of Mountain Biking. The scene in the late 1970's and early 1980's was much different in Marin. The times have changed and WTB has evolved and is now making tires, saddles, grips and their own rims. We gave them a call to get a set of Vigilante tires to test out. Our terrain is about 85% rock with spattering sections of soil the dusty kind with no traction and marbled out high speed loose trails with no berms. It takes a hell of a tire to perform well in San Luis Obispo.

"WTB was founded in Marin County, California in 1982, fueled by the need to create durable and reliable mountain bike-specific equipment. Back then mountain biking was a new and burgeoning sport, and mountain bikes weren’t much more than cobbled-together oddities. The original WTB crew was captivated by the experience of riding bikes on dirt trails, and they started creating more durable and functional components for their own bikes. Soon, local frame builders sought to outfit their bikes with WTB’s high-end components. WTB was able to turn our passion for bikes into a successful business.

Today WTB is a global enterprise; our innovative components are used for trail riding, transportation, recreation and elite racing across the globe. After 30 years things have changed a bit here at WTB–our little garage has morphed into a real office and the bikes we ride and the components we make have evolved to meet the needs of today’s riders, racers, and commuters. What hasn’t changed is our passion for cycling and our commitment to providing the cycling community with durable, reliable, high-performance components."

We contacted WTB to get ahold of some of their latest tire offerings. A week later we had a box with Vigilante, Riddler and Breakout tires to test out. We are running The Vigilante tire as a front tire with The Riddler as the rear tire. Many riders in our area have been raving about The Vigilante since it first came out. Our terrain is very rocky, dry and loose. Basically for ten months out of the year you are riding on marbles.

"Born from the need to race in European enduro events, the Vigilante is our premier aggressive All Mountain tire, and first choice for Team WTB’s Mark Weir. The square-lugged, open-tread pattern offers stability in loose or wet terrain, while the stiff outside knobs grip at lean angles like nobody’s business. With Dual DNA (TCS) and Gravity DNA (Team Issue) rubber, this is the tire to ride when you are giving it your all."

Mounting the WTB Vigilante was a snap. We did it with a floor pump and without using soap mounting them to 30mm rims!The Easton ARC did ever so slightly flatten out the Vigilante's tread profile BTW. We had the 27.5 2.3 TCS Tough Fast Roll casing our tire weighed 1055 grams. That is a bit more than advertised but we have seen DH tires vary by 200 grams! If you are that worried weigh each tire in the store before making a purchase.

WTB Vigilante Fast Rolling Features

- Available in 26", 27.5"/650b, and 29" sizes

- Actual Weights:

- 27.5x2.3 TCS Light Fast Roll - 837 grams

- 27.5x2.3 TCS Tough Fast Roll - 1014 grams

- Actual Widths:

- Casing: 27.5x2.3 - 2.25"

- Tread: 27.5x2.3 - 2.26"

- Aramid Bead

- 60 tpi

- TCS - Tubeless Compatible System - Uses sealant to seal inside of tire, will NOT hold air without sealant

- Open tread blocks roll fast

- Reinforced cornering knobs grip predictabily in a wide variety of trail conditions

- Enduro casing: Dual layer (TCS Tough)

- Lightweight casing: Supple and conforming (TCS Light)

- Fast Roll: 60a durometer compound

- High Grip: 45a durometer compound

- Made in Taiwan

- Two Year Warranty

Our first ride on the Vigilante was on a trail that we ride every week. It is about 700 feet to the top and getting back down it takes around 4 minutes. There had been a good deal of rain the last few weeks so our soil that usually feels like you are riding on ice was actually providing decent traction. Entering the first few turns I was shocked how much bite the tire was offering both in braking and while being leaned over. The fourth turn on this trail is a severe off-camber left hander that is very sharp about 120 degrees the front of the bike offered copious amounts of grip and i just got the rear to brake loose with a dab of the brakes.

The next trail is about 900 feet to the top. Fast times going down are about 2:30 or so. This trail has a rock garden that is about 300 yards in length. After that you enter the trees and begin riding on a hard pack dirt. This section is very fast and filled with fast gradual turns. I was running 25 PSI on the front tire and just below 30 on the rear. Even though we had the fast roll version the front tire still offered very good traction in the baby heads. Lower down the trail the Vigilante did well in the high speed hard pack.

San Luis Obispo is know for having fast loose and rocky trail. That was what the next trail is know for. I can do it in 9 minutes the record is in the low 7 minute range. On this trail you can easily get up to 30 mph on the top section. It is fire road width and filled with good size embedded rocks (the kind that pinch flat) and for good measure these are coated with smaller loose rocks to make it extra slippery! I pinged my rim a few times hard and the tires had no issue. There are a few corners that are long and off camber and when riding an aggressive trail bike you need to be pressing the front end down. WTB seemed to have done a good job with The Vigilante they offered great traction on the loose rocks. I know the sticky version would have been even better!

There is a trail in town that is short and pretty rocky. Not exactly Santa Barbara rocky but has some good size rocks in it. The rocks here range from golf ball up to beach ball in size. They are almost all round so it can be fun to bounce through them. Tires that are super sticky will allow a rider to cut edges off of these rocks easily. The WTB Vigilante was almost able to do this. It slid off of some of the smooth rounded rocks and others it held enough traction to let me glide over an edge. I think the tacky version would have been incredible here. Overall the tire did very well and in fact I got one of my fastest times down this trail and I had not ridden it in almost 6 months!

Being close to the ocean provides us with trails that are more sand based. These are great to ride post rain or even during the rain. I went out here and made my way up the hill it is about 800 feet to the top. fast riders can get down in under 8 minutes it usually takes me 9 minutes. This trail is very fast to start then you drop down into a valley and it is filled with turns and rocks. Lower down you are floating on top of a fine sand layer and things can get twitchy at speed. The WTB Vigilante did well on this sand filled trail. The tire held traction in the turns and had no issues crushing over the rocks. Lower down it floated its way over the sand without issue. I went and road this during a heavy downpour and the tires worked incredible in these lower sandy turns BTW.

Conclusion

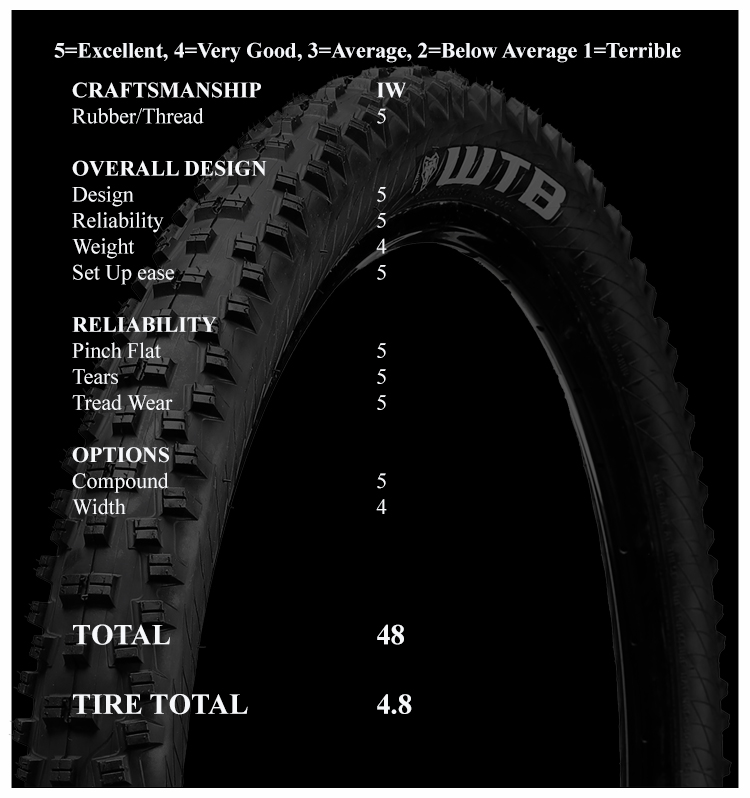

Overall I was very impressed with The WTB Vigilante tire. It worked very well as a front tire on our traction deprived trails. They did a good job making a tough casing that will tolerate low PSI and not tear of flat easily. The tire did well in rock, hard pack and sandy trails. I also did some riding when it was pretty wet out and it did decent in light mud as well.

This isn't the lightest tire out there Maxxis has some around the 900 gram mark that work well. They do make a lighter version if weight is a big concern for you. Having a tire that sticks in varying types of terrain is great. This is a tire I would highly recommend to a friend and will for sure be buying to mount onto personal bikes down the road.

Q & A With WTB

Q & A With WTB

1. Give us a “quick” history of WTB.

Started early with the idea of doing what was not already done. Making parts to provide for complete bikes led to surplus production and bike shop sales. Maturing markets took WTB from designing for others to promoting the WTB brand and production in Asia for OE and replacement parts. The soul has never been lost though the price point pressure is high.

2. What goals or concerns did you have when designing the Vigilante?

Deep digging in softer terrain with enough block mass for precision tracking on hard ground. We designed the open tread pattern to shed, as well as spike, the turf when soft enough. Paired with outer edges positioned to pick up maximum lean angle and spaced to conform to irregularities so as not to bounce off as denser outer spaced tires do.

3. Was weight, reliability or traction the biggest concern?

Traction was the biggest concern. Reliability is usually about rider finesse and whatever terrain comes along. Weight is always a concern, but making tire casings tougher for more extreme use is always a possibility. In the lightest embodiment, Vigilante is reasonably tough.

4. Who created the tread design?

WTB has a variety of people that have an influence on how the various tread patterns produced get done. Drawings that are submitted to mold makers are a culmination of design input.

5. Are you guys going to come up with a 2.5 version of the tire?

We’re always working towards meeting the needs of riders and developing new tires according. Something to consider…mounting the 2.3 on a wider rim would get towards a 2.5 width. This is based on10mm of inner rim width equating to about 4mm of tire section width.

6. What about a tire with multiple durometers? (60/42)

Currently, all our TCS tires utilize two compounds of different durometer ratings to keep the tire fast and durable where needed, as well as soft and tacky where needed. Regarding a Vigilante with a 60/42 durometer, the standard answer is that WTB does what we can based upon sales volume. However, the passion for better product is where we started and what drives us. So, based on what we hear, and what we surmise relative to testing ourselves, WTB will produce the best product possible. Durometer measurements can be subjective, but 60/42 sounds like a good one to try.

7. When will a fat bike win an EWS race?

When it all freezes over and flotation is the only way to make time and speed.

8. What would help the bike industry the most? ($, lowering cost, more trail access)

More people on more bikes more often in more places. If the bike industry makes more money, it will most likely put it into product technology and marketing. Most companies won’t spend a large part of the profit on advocacy, as WTB does. We spend so much on bike advocacy that it actually harms our business at times. Lowering cost is a human rights issue. We don’t support low quality of life for the people who make bike parts and nor should anybody else. Lack of trail access can make it hard, or impossible, to ride mountain bikes in an efficient manner. You see this in areas where the only way to get in a good ride is to jump in the car and drive hours. You basically have to take a half, or whole, day to go on a decent ride when driving is involved. Easy access to trails for everyone will allow bike sales to flourish.

9. Who is the better rider Nico, Tomac or ACC?

If you ain’t first, you’re last! Let the results do the talking. We are not fit to judge. Better yet, ask each of them about the other.

10. How is the hiker/biker conflict in Marin these days?

Cooled out for the most part. The best interaction is none at all. In the last couple of years we’ve seen a lot more public discussion between both parties on the issue of trail access, and how to best share the open space that we all enjoy. Facilities like the Stafford Lake Bike Park opening up provide great opportunities to showcase our cycling community, as well as teach up-and-comers bike skills and trail etiquette. We think things will only improve given the amount of cyclists in Marin, it just takes time and careful planning.

12. What is with all the new “standards” the last 5 years?

Improving the breed requires vigilance. Standards do not become “standard” unless they are worthwhile. And just like science they are only as good as the current best effort and knowledge.

13. Can America make a race organization that will surpass the UCI? Like real payouts and corporate sponsorship?

That is doubtful, for now. Mountain bike riding is increasing in the states, mostly due to NICA (National Interscholastic Cycling Association), which is getting the next generation of riders on bikes. In turn, more parents and family members of these youth are getting on bikes as well. This builds fans of the sport, and fans of racing, which will ultimately feed America’s hunger to have more high-level races on our home turf and increase support for the organization of a solid cycling federation. Surpassing the UCI is a hefty goal, but thinking bigger is how we get outside the box.

14. Anything you want our readers to know about the Vigilante?

That it is designed to be the go-to tread for all-round use. That there are other choices for harder ground and longer tire life. That it is not the fastest rolling tire WTB offers but it should keep riders happy that want to ride in all conditions.

WTB,

WTB,  WTB Tire,

WTB Tire,  WTB Vigilante,

WTB Vigilante,  WTB Vigilante Tire Test |

WTB Vigilante Tire Test |

Hope Crankset Review

Tuesday, February 23, 2016 at 4:19PM

Tuesday, February 23, 2016 at 4:19PM  Permalink

Permalink

Hope Technology has been around for almost 40 years now. They began making their first disc brakes in the late 1980's. Over the years they have expanded their production to include hubs, stems, pedals, headsets, cranks, BB's, chain rings and a cassette is now in the works. They pride themselves with making all their parts in their home country of England.

Over the years we have owned many Hope products personally. Including Bulb and Big Un hubs, Mono 4, Moto V4 and and the newer Tech V4 brakes. All of their products worked well and their brakes in the past where nothing short of amazing. We decided to get the Hope Cranks to test out on the "enduro" bike and see how these machined works of art performed going "full enduro".

"Hope Technology began life in the late 1980’s as a subcontract machining business making tools and fixtures for the many local aerospace companies. In 1989 they began making disc brakes for the newly developed mountain bikes. Initially for the personal use of the owners Ian Weatherill and Simon Sharp but they quickly realised these brakes could be sold as a product in their own right.

Since disc brakes were such a novel idea on a bicycle they decided to begin manufacturing other more common bicycle products, the first of these being a front hub. These began selling through retailers in the UK and interest was also shown in many countries around the world.

Over the subsequent years many more products were added to the range and in 2000 the decision was made to stop all subcontract work and concentrate purely on bicycle products.

Hope now manufactures almost every part for a bicycle including hubs, brakes, headset, stems, bottom brackets and lights. The only major part left to develop is the actual frame, which may be happening in the not too distant future. All parts are proudly manufactured in Hope’s Barnoldswick factory which is a true state of the art facility. They have almost 100 staff operating the factory 24-7, running the 55 CNC machines, anodising the individual components and hand assembling the finished parts. Manufacturing all products on site gives Hope total control on quality and delivery schedules.

Hope exports around 50% of its production to over 40 countries. They deal directly with retailers in the UK, France, Germany, Austria, Belgium and The Netherlands (employing French and German speaking staff), then have distributors in many other countries. Their components have an excellent international reputation for both quality and reliability. They are generally fitted by enthusiasts looking to upgrade their bikes to the highest levels and are supplied through specialist retailers."

We took our time installing the Hope Cranks into our Evil Insurgent frame. It went in easily and we applied ample grease to the threads in the BB. Once you install the cranks having to take them apart to clean or grease them will take no longer than a traditional crank set would. I am not sure if the expanding spline arm interface is a better way to hold the cranks together or just being done for difference sake. They certainly stayed tight and squeak free for the 5 months we rode them.

Hope Crankset Features

- Forged and CNC machined 7075 series aluminium alloy crank arms

- Unique expanding spline/arm interface (patent pending)

- Versatile Spline mount for chainring/spider

- 165, 170 and 175mm length

- 30mm oversized axle

- Arms available in black, blue, red, silver, purple and orange

- Different axle length options available to accommodate most bikes from XC, DH and FAT bikes

- Weight: 641g (arms, axle and 34 tooth spiderless ring)

Hope Crankset Tech Specs

- Developed over many years the Hope crank has been designed using the latest FEA (Finite Element Analysis) tools and extensive multi discipline field testing.

- The cranks feature a unique expanding spline axle/arm interface (pat pending) and incredibly versatile spline mounted spider/chainring system.

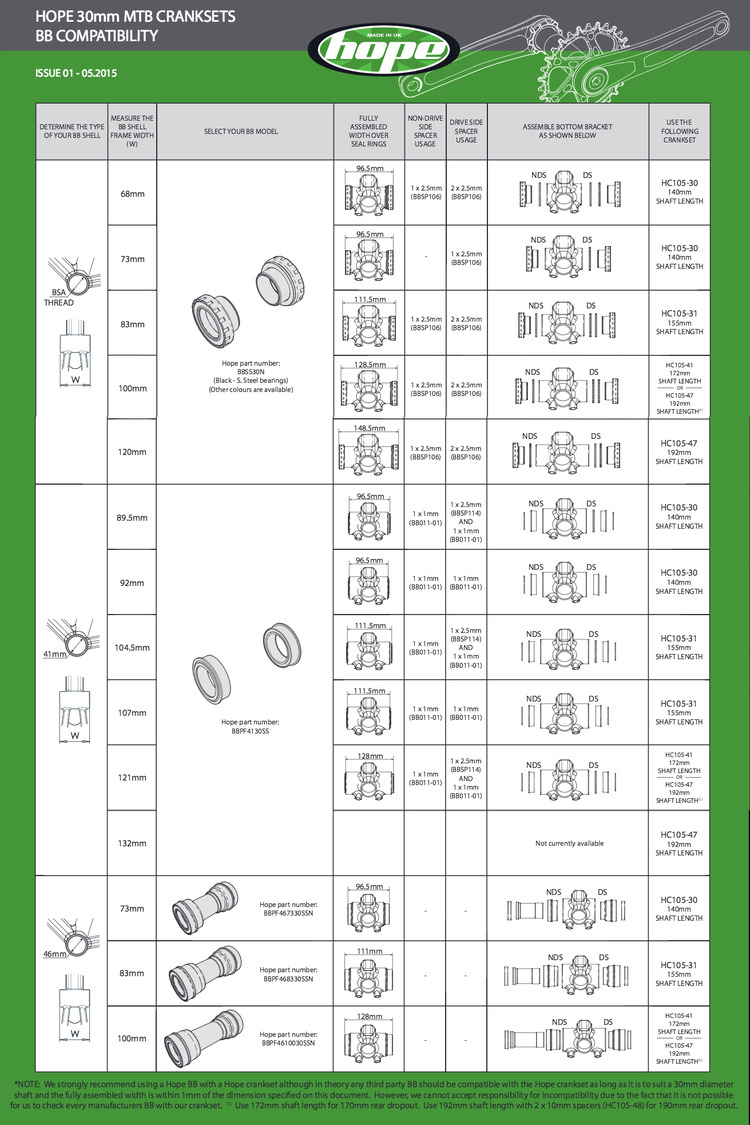

- Our expanded range of bottom brackets ensure compatibility with most bottom bracket systems (See hope cranks compatibility chart)

- Q‐Factor & Chainline- see "crankset fit and chainline" document.

- Several spindle length options available to accommodate most bikes (from XC to DH, including FAT bikes) "see Hope cranks BB compatibility chart".

- Chainring mounting:9, 10 and 11 speed compatible

- Spiderless Retainer chainrings 26T to 36T

- Spider Single 104BCD and Double 64/104BCD (with provisional room for a bashguard on all spiders)

Hope 30mm BB Compatibility

Hope packages the cranks in a clean looking box with foam holding everything secure. Opening the box we found beautiful looking cranks. Hope has been producing high end Mountain Bike components for close to 30 years. Their fit and finish are top notch. Hope includes instructions with the cranks. Make sure you read these as you install the cranks onto the bike. We took our time and everything went together as it should. Their suggested BB spacing was also correct BTW.

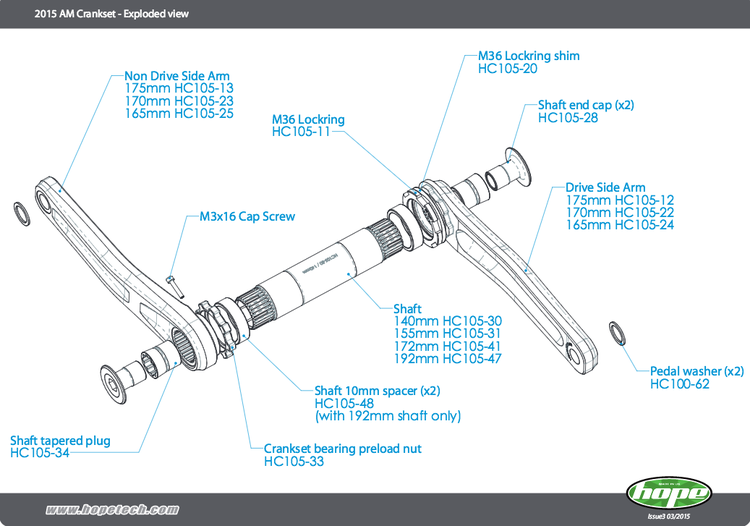

Hope Cranks Exploded View

The Hope cranks are a bit heavier than some of their carbon counterparts. The nice thing is that aluminum cranks can take some serious rock strikes without worrying about any possible cracking issues like a carbon crank. If you look at other aluminum cranks they are right there in that 600 gram range. Another thing to think about is labor standards, pollution, and how renewable a material is.

Ian W

The Hope cranks proved to be a reliable and silent operator. We checked them every once in a while and they never needed to be tightened. Hope's spline interface is unique and seems to do a good job at holding the cranks together.

We had ample time aboard the cranks. They never loosened up made a noise or needed any service in the 5 months we rode them. We have used numerous Carbon cranks over the last 3 years. Going carbon could save 200-300 grams in the crank arms but being able to smash crank arms into rocks at close to 30 MPH and not worry is priceless.

Hope products all have some of the best fit and finish in the business. Their cranks are no exception they seem to bleed quality. We put a fair number of miles on these cranks with no issues. During our testing period they never made a noise and only once after the first few rides did they need to be tightened up some.

Conclusion

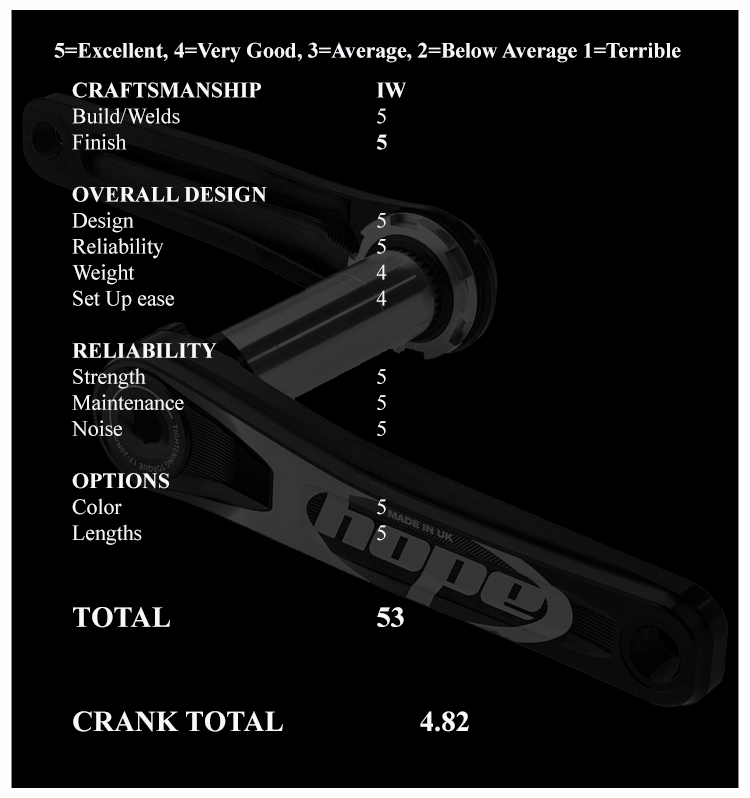

Overall we where very impressed with The Hope Cranks. They are a quality piece of kit that can be bought for half the price of their carbon counterparts and will not crack under hard strikes. Their craftsmanship is beautiful and the design functional.

Having some many choices in cranks to choose from is a good thing for the consumer. Suggesting The Hope Cranks to a friend would be a no brainer. The price, build quality and weight are all great.

When looking for your next set of cranks check out what Hope has to offer. Using forged and CNC machined 7075 series aluminium alloy crank arms along with a 30mm axle stiffness will not be a concern. I did notice their thin profile gave me a bit more room to place my feet on the flat pedals. Some of the carbon cranks we have been using are noticeably thicker. Hope offers their cranks in a wide assortment of lengths and colors.

A short video showing the fitting and removal of Hope Cranks.

Hope Crank Set Q n A

1. What was Hope's primary goal in creating and designing the cranks?

As with all our products, we're making a part we needed for our own bikes.

2. Can you please explain the axle interface being used on your cranks?

We use an expanding spline. This means that even after the cranks have been removed several times, they can still be refitted as securely as the first time, without creaking! Many cranks relying on tapered splines become worn and don't offer this reliability.

3. Was weight or stiffness of more importance?

Weight is never our primary goal. All our products must perform first, then we look at the weight. As it turned out though, with using a forged crank arm we've managed to produce a stiff crank, at the lower end of the weight range. So they're still light enough for an XC bike, yet stiff enough for DH

4. Is it hard building cranks with all the different standards and Q Factors being used these days?

Not with the modular crank system we've created. All the crank arms are the same, but you simply fit different axles for different width frames. We can also accommodate boost simply by swapping the spider/direct mount chainring.

5. Any tips for installing The Hope Cranks?

Yes – make sure you read the instructions. Sounds obvious but our cranks look similar to some other brands, but they are pulled onto the splines differently.

6. What is the most popular crank arm length would you say?

Has to be 175mm

7. Hope has been around a very long time can you give us a brief overview of the company?

Hope was started in the late 80's by friends Ian Weatherill and Simon Sharp. They were toolmakers and left Rolls Royce to setup their own tool making business. Coming from a motorcycle trials background they weren't happy with the brakes on their bikes so along with one of the guys working for them they designed a bicycle disc brake. They began selling them along with hubs, but initially it was the hubs that really took off. This idea of making parts for ourselves has continued through to the present day. We're probably one of the first 'rider owned' companies in mountain biking, with Ian and Simon still having complete ownership of the company and coming into the factory everyday.

8. What do you think were the top 3 advancements in MTB technology in the last 20 years?

Disc brakes (little bias), suspension and the dropper seat post.

9. Climbs or descents?

Descents every time- it’s what makes the climbs worth it!

10. Rocks or jumps? Rocks

11. What do you think the future holds for the industry as a whole?

The worry is that this explosion of wheel sizes could put off riders from continuing with mountain biking as a sport. They will think it's simply too confusing.

12. Would you rather have the skills of Nico or Ricky Carmichael in their primes? Nico

13. Is it hard for you guys to keep production in England and still keep you prices close to competitors that have moved production to Asia?

Not really since we're in the upper end of the market. We can't make the true mass production parts of the lower end, but if it's high end performance parts then it's achievable.

13. You have been teasing some carbon bars, and bike frames recently are you going to see these soon?

Watch this space….

Hope Crank Review,

Hope Crank Review,  Hope Crank Test,

Hope Crank Test,  Hope Cranks,

Hope Cranks,  Hope Technology |

Hope Technology |